The BMX 45Y2 is equipped with two rugged and quick Biglia servo turrets.

Live tooling on all positions. Up to 30 tools can work simultaneously.

The rotary tools are driven by a motor with 22 Nm torque, 2,2/4.6 kW power

and speed range of 6000 rpm/min.

Live tooling

BMX 45Y2

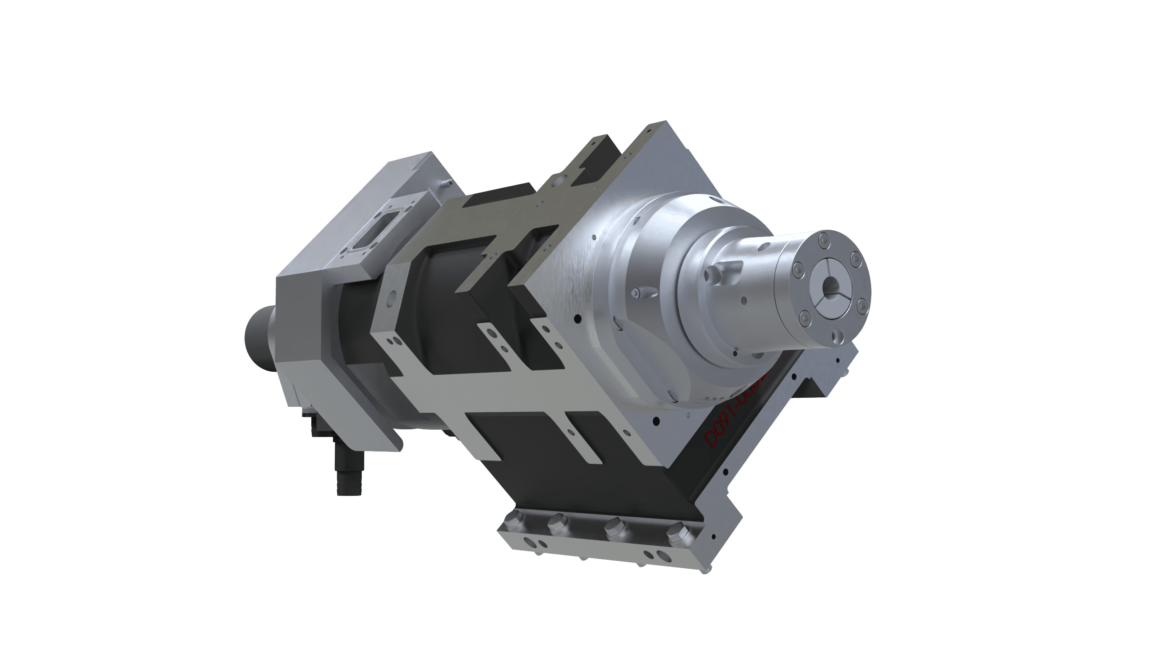

The BMX 45Y2 is equipped with two liquid cooled integral motor-spindles which are driven by high-performance motors (11kW power and 6000 rpm spindle speed). These spindles allow powerful cutting as well as exceptional surface finish and roundness accuracy.

Spindles

BMX 45Y2

The position of the CNC-operated sub-spindle featuring a double movement (longitudinal and

transversal – Z3 and X3 axes) enables reliable and flexible machining operations.

The sub-spindle can be offset from the main spindle.

The main advantages are:

Sub-spindle

BMX 45Y2

- elimination of interference problems between the two turrets

- simultaneous “follow up” machining using three tools thanks to the “Superimposition” function

- possibility to use the sub-spindle as a regular tailstock to hold the component machined on the

main spindle with T1 and simultaneously perform finishing with T2

Compare the models in the family to find the one that best suits your needs