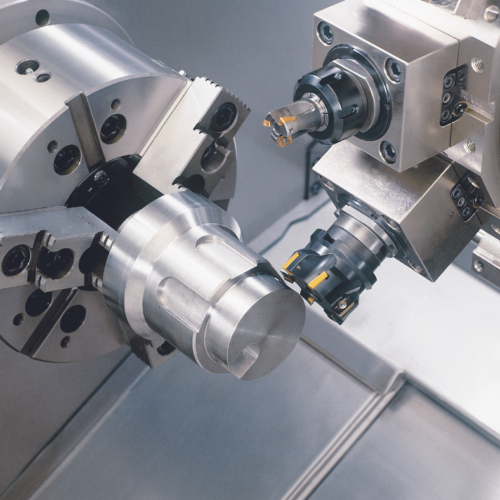

This new turret equipped with a cooled direct drive built-in spindle motor (10-17,5 kW - max. 10000* rpm) to drive the rotary tools represents the main feature of the new B750/B1250 series.

Live tools

B1250

ASA 8" Ø82mm

B1250

ASA 8" Ø95 / 102.5mm

B1250

Sub-spindle

B1250

The work-piece is automatically transferred from the main to the sub-spindle to allow the complete machining process on both sides.

The sub-spindle is equipped with B-axis load detection system and pneumatic ejector to check presence of the component (option) which allows you to perform safe machining operations.

CNC automatic tailstock (B-axis)

B1250

Both B750 and B1250 range of machines are equipped with the tailstock body that slides on flat slide-ways. Positioning is fully automatic.

The tailstock is operated by a servo motor and ballscrew (B-axis). This solution improves operating flexibility since position and thrust are CNC-controlled. It can also be used to perform simultaneously both drilling and turning.

Hydraulic tailstock

B1250

The tailstock is positioned by the turret-holding carriage (Z-axis). The stroke of the 115 mm diameter hydraulic quill is 150 mm. A rotating tailstock integrated to the quill is offered as an option on both B750/B1250.

AVAILABLE VERSIONS

B1250

Standard machine with CNC automatic tailstock

B1250M

Rotary tools (12/16)

C-axis

CNC automatic tailstock

B1250SM

Rotary tools (12/16)

C-axis on the main spindle

C-axis on the second spindle

B1250Y

Rotary tools (12/16)

C-axis

Y-axis

CNC automatic tailstock

B1250YS

Rotary tools (12/16)

C-axis on the main spindle

Y-axis

C-axis on the second spindle